how does a brushless hub motor work

In fact many users of a hub motor put the bike in one of the higher gears and never need to shift gears ever again. There are two basic categories of hub motors.

Yescom 26in Front Electric Bicycle Motor Conversion Kit 48v 1000w Electric Bicycle Kit Electric Bike Kits Electric Bike Conversion

The controller provides pulses of current to the motor windings which control the speed and torque of the synchronous motor.

. The way a brushless motor works is by using electromagnets rather than brushes to spin the motor. Brushless DC motor how does it works. Then the controller activates the coils.

Magnetically charged permanent magnets are attached to the rotor of the motor. The most commonly used hub motor is Brushless DC motor owing to its high torque to weight ratio. This makes it easy for the novice to install on a bike and the result is a quiet ride that is never in the wrong gear.

In brushless DC motors the permanent magnets are on the rotor and the electromagnets are on the stator. This means that the wheel is simply a motor with the shaft fixed in place so that the body. Electromagnets can also be used to generate power.

In a brushless DC motor BLDC you put the permanent magnets on the rotor and you move the electromagnets to the stator. With a hub motor conversion there is no need for external mounting brackets and drive chains to support a motor and transmission. The magnets are attached to the motors bell and push and pull the motor as necessary.

It helps regulate the current injected into the rotors windings and run the commutation process more smoothly and efficiently. It is commonly used in electric bicycle. The outer shell of the hub is part of the motor and has a big ring of strong rare-earth magnets fixed to it.

Thats where your name comes from. The working of an electrical motor is simple. If only connecting a fixed DC current to the motor the motor can.

While some older electrical devices may use what is known as a brushed DC motor a good electric bike motor is brushless. A basic brushless motor is a dc motor. This means that as the motor is used and ages the brush can wear away break.

After the right amount of power gets to the motor it energizes the magnets to spin the e-scooter shaft turns the. The hub motor is usually coupled to the wheels with speed controllers in order to vary the speed of movement of the bicycle. The structure of Brushless DC Motor BLDC is shown in figure below.

Instead all of this is contained inside the wheel which mounts on your bike like any other wheel. A Brushless DC Motor BLDC accomplishes commutation electronically using rotor position feedback to determine when to switch the current. Answer 1 of 6.

They utilize direct current powering magnets to move the rotor within the stator. Help us to make future videos for you. With the advent of cheap computers and power transistors it became possible to turn the motor inside out and eliminate the brushes.

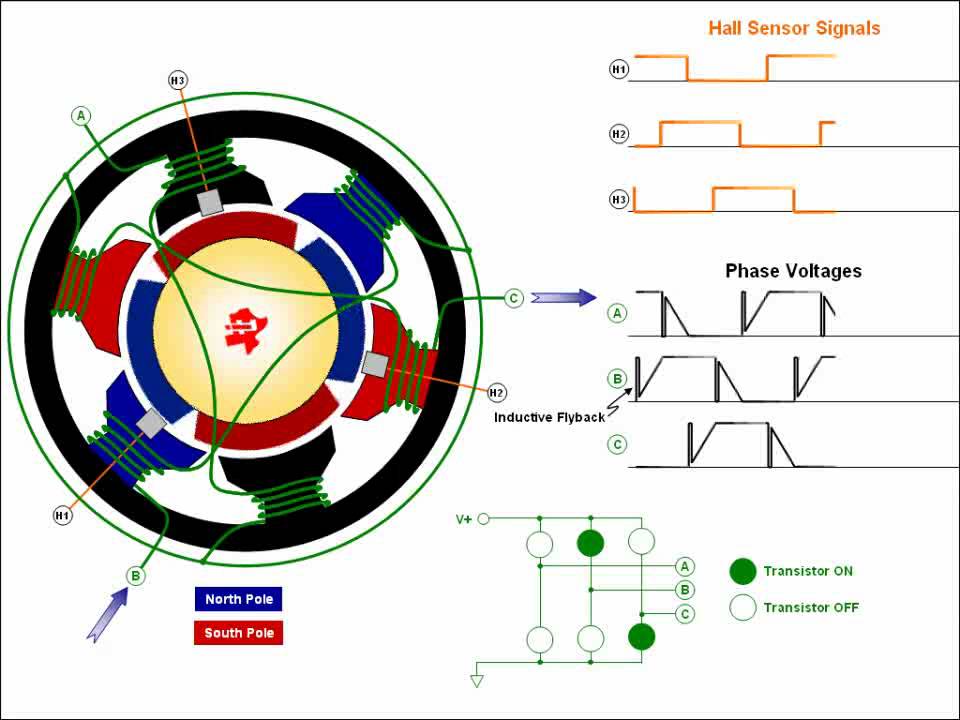

Make LEs efforts sustainable. The direct drive motor photo above right is the simplest. In addition it uses three phases of driving coils and three hall sensors to track the rotor position.

The BLDC motor is electrically commutated by power switches instead of brushes. Then you use a computer connected to high-power transistors to charge up the electromagnets as the shaft turns. E-BikeKit has chosen the hub type electric bike motor for all of our kits.

The circuit switches the power on and off in the coils in turn creating forces in each one that make the motor spin. A computer then charges the electromagnets in the stator to rotate the rotor a full 360-degrees. In order to detect the polarity of the motor rotor a position sensor is provided in the motor.

Instead of using brushes and a commutator the motors use a step motor controller. Brushless DC motors typically have an efficiency of 85-90 while brushed motors are usually only 75-80. The direct drive hub motor is about as simple as things get.

With the hub motor the motor is actually located right inside the hub of the wheel. The battery supplies power to the controller which determines the amount to send to the motor. The magnetic fields created when the coils are generated exert a pushpull force on the permanent magnets arranged around the outside of the casing.

Its rotating member has magnets typically 4 or 6 on it that create a permanent magnetic pm field. Direct drive and geared. Hub motors are typically brushless motors sometimes called brushless direct current motors or BLDCs which replace the commutator and brushes with half-a-dozen or more separate coils and an electronic circuit.

A brushless motor utilizes a permanent magnet as its external rotor or internal rotor. The stationary part the stator has windings that create a magnetic field when current is put through the winding wire. In an old-fashioned brushed motor the brush is a piece that conducts electricity serving as a go-between from stationary wires and the moving parts of the motor itself.

The stator of brushless DC motor is coil winding armature and the rotor is a permanent magnet. When the motor runs it drives the wheel directly. Typically a sinusoidal brushless motor controller circuit uses pulse-width modulation PWM.

What are Brushless DC Motors Used For. Brushless Hub Motors. Like brushed DC motors brushless motors work by alternating the polarity of the windings on the interior of the motor.

When the sensor tracks the rotor position it sends out reference signals to the controller. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. A hub motor is a electrical motor coupled to the wheels of a vehicle.

A brushless DC motor also known as a BLDC motor or BL motor is an electronically commuted DC motor which does not have brushes. The brushless DC BLDC motors increasing popularity is due to the use of electronic commutation. This replaces the conventional mechanics comprised of brushes rubbing on the commutator to energize the windings in the armature of a DC motor.

Brushless motors are synchronous electric motors that move around electronically.

Brushless Dc Motor Diagram Best Electric Scooter Electronics Basics Electronics Mini Projects

8000w 16inch Brushless Hub Motor For Electric Scooter Electric Bike Kits Electric Scooter Scooter

Bldc Hub Motor Youtube Electrical Motor Motor Electricity

Electric Car Hub Motor 273 4000w Extra Type V3 In Wheel Hub Motor In Atv Parts Accessories From Automobi Diy Electric Car Electric Car Electric Motor For Car

Build Your Own Hub Motor Electricity Diy Electronics Motor

How Do Hub Motors Work Brushless Bldc Electric Motors Electric Bicycle Bike Electric Motor

Thelashop 48v 1000w 26 Inch Front Rear Electric Bicycle Motor Conversion Kit Electric Bike Diy Electric Bicycle Conversion Kit Electric Bicycle

Pedal First Vs Instant Start Brushless Motor Controllers Youtube Electric Bike Diy Ebike Electric Bicycle Electric Bike Motor

Motor Tuning How Electric Motors Work Electric Motor Motor

In Wheel Motors Electric Car Conversion Electric Cars Electric Motor For Car

Disc Type 12n16p Dc Brushless Motor Permanent Magnet Outer Rotor Motor Hub Motor Diy With Sense Hall Has Been Wound Tesla Technology Electrical Motor Disc Type

How Brushless Motor And Esc Work Howtomechatronics Free Energy Projects Free Energy Electronics Projects For Beginners

Brushless Gearless Electric Scooter Wheel 500w Hub Motor 48v Scooter Wheels Electric Bike Kits Electric Bike Diy

How Electric Vehicle Hub Motor Works Construction Working Types Hindi India Explained Youtube Elect Motor Works Electric Cars Electric Bicycle

Pin By Grzegorz Snug On Robot Air Conditioning System Motor Electronics Basics

Pin On Wheel Hub Motor Winding Machine

E Bike Spoke Motor 48volt 1000w Brushless Dc Hub Motor For Rear Wheel E Bike Electrical Bicycle Electric Bicycle Electric Bike Kits Bike Kit

How Do Hub Motors Work Brushless Bldc Electric Motors Electric Motor Motor Electric Bike